Great Bear Reports 97% Gold Recoveries from Preliminary Dixie Limb Zone Metallurgical Testing

January 27, 2021 – Vancouver, British Columbia, Canada – Great Bear Resources Ltd. (the "Company" or "Great Bear", TSX-V: GBR; OTCQX: GTBAF) today reported gold recovery test results from its 100% owned flagship Dixie Project, in the Red Lake district of Ontario.

Chris Taylor, President and CEO of Great Bear said, “We are very pleased to report that our first metallurgical tests from the Dixie Limb zone have recovered 88 – 97.5 % of head grade gold values from conventional cyanidation bottle roll leach tests. These results confirm gold mineralization at the Dixie Limb yields similar very high gold recoveries to those previously reported from the Hinge zone. Over the coming months we will periodically release gold recovery results from representative samples originating from all of our gold zones including the LP Fault.”

Metallurgical tests confirm very high gold recoveries with minimal impact from either accessory sulphides or the argillite host rocks which are frequently present in the Dixie Limb zone. Table 1, Table 2, and Figure 1.

High Sulphide Samples

The Dixie Limb zone contains both low and high sulphide content mineralization types. Dixie Limb zone gold mineralization with low accessory sulphide content within quartz veins is mineralogically indistinguishable from the adjacent Hinge zone mineralization, which previously yielded very high gold recoveries of 95 – 97% (November 12, 2020). This material was not re-tested.

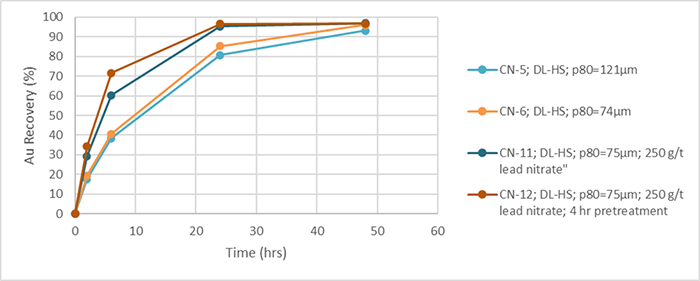

Four high accessory sulphide (pyrrhotite and pyrite dominated) samples were tested for the first time using the same metallurgical processes as were previously applied at the Hinge zone. Additionally, lead nitrate, a common additive to gold recovery circuits at deposits containing significant accessory pyrrhotite, was added to two of the high sulphide samples.

Gold recoveries were very high for all samples, returning similar results to Hinge zone low-sulphide samples.

- More finely ground material yielded slightly higher recoveries (93.1% for more coarsely ground versus 96.1% for more finely ground material).

- Faster gold dissolution kinetics and slightly higher gold recoveries were noted for the samples treated with lead nitrate (96.1% without lead nitrate versus 96.9% and 96.7% with).

Table 1: Gold recoveries from Dixie Limb zone material with high sulphide accessory mineral content.

| Test ID | NaCN Concentration (g/L) | Lead Nitrate (g/t) | % Solids | Primary Grind (p80, µm) | 48 hr Au Recovery (%) | Cyanide Consumption (NaCN, g/t) | Calculated Head Grade (Au, g/t) |

| CN-5 | 1.0 | 0 | 40 | 121 | 93.1 | 1.11 | 8.99 |

| CN-6 | 1.0 | 0 | 40 | 74 | 96.1 | 1.91 | 8.92 |

| CN-11 | 1.0 | 250 | 40 | 76 | 96.9 | 1.55 | 9.35 |

| CN-12 | 1.0 | 250 | 40 | 77 | 96.7 | 1.35 | 8.80 |

Figure 1: Dixie Limb zone gold recovery curves showing time-weighted recoveries from high sulphide material.

Argillite Samples

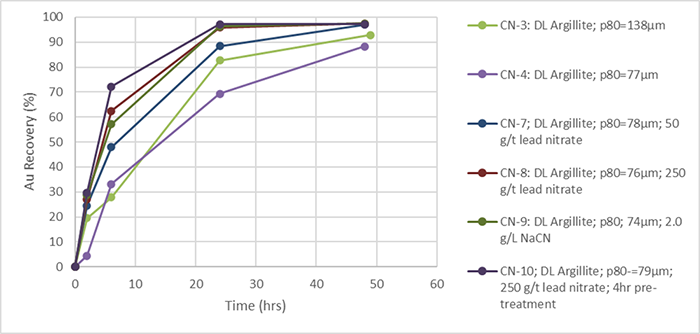

Gold mineralized argillite is present at the Dixie Limb zone but not in the other gold zones at Dixie. Six gold mineralized argillite samples were tested using the same metallurgical processes applied to the Hinge zone and the high sulphide Dixie Limb zone samples, i.e. variations in primary grind size and addition of lead nitrate. A higher cyanide concentration was also analyzed for the first time.

All gold recoveries in all conditions were very high, similar to non-argillite Hinge and Dixie Limb zone samples.

- Finer grind size had no effect on gold recoveries, which were high for both coarse and fine grinds (samples CN-3 and CN-4; 92.9% and 88.3% respectively).

- Increased cyanide concentration yielded a slight increase in gold recovery (sample CN-9; 97.5%).

- In the argillite material, the addition of lead nitrate increased the rate of gold dissolution, while reducing the overall consumption of cyanide. Gold recoveries were also modestly increased by the addition of lead nitrate (samples CN-7, CN-8 and CN-10; 97.0%, 97.4% and 97.1% respectively).

Table 2: Gold recoveries from Dixie Limb zone material hosted by argillite.

| Test ID | NaCN Concentration (g/L) | Lead Nitrate (g/t) | % Solids | Primary Grind (p80, µm) | 48 hr Au Recovery (%) | Cyanide Consumption (NaCN, kg/t) | Calculated Head Grade (Au, g/t) |

| CN-3 | 1.0 | 0 | 40 | 138 | 92.9 | 1.10 | 10.07 |

| CN-4 | 1.0 | 0 | 40 | 77 | 88.3 | 4.47 | 10.89 |

| CN-7 | 1.0 | 50 | 40 | 78 | 97.0 | 1.66 | 10.37 |

| CN-8 | 1.0 | 250 | 40 | 76 | 97.4 | 1.43 | 11.06 |

| CN-9 | 2.0 | 0 | 40 | 74 | 97.5 | 3.30 | 11.49 |

| CN-10 | 1.0 | 250 | 40 | 79 | 97.1 | 1.56 | 9.35 |

Figure 2: Dixie Limb zone gold recovery curves showing time-weighted recoveries from Argillite material.

Impact of Metallurgical Studies To Date

Metallurgical results to date suggest similar gold recovery processes are applicable to both the Dixie Limb and Hinge zone. Metallurgical testing of samples from the LP Fault zone is underway, with results expected periodically over the remainder of 2021.

The Company will also begin gravity circuit gold recovery tests on samples from all gold zones in 2021.

Details of Dixie Limb Gold Recovery Work

- Ten one kilogram samples were analyzed by Blue Coast Research Ltd. of Parksville, British Columbia during these preliminary metallurgical tests.

- These ten samples were taken from two aggregate composites which had the following representative geological characteristics:

- A high sulphide composite of 18.96 kilograms representing 20.10 metres of core length, averaging 8.0 g/t gold.

- A sedimentary host (argillite) composite of 18.6 kilograms representing 11.95 metres of core length, averaging 10.6 g/t gold.

- Samples were processed through a standard 48 hour bottle roll procedure at 40% solids, using a 1.0 g/L sodium cyanide solution. Other conditions, such as grind size and lead nitrate addition, were varied according to the test objectives.

About the Dixie Project

The Dixie Project is 100% owned, comprised of 9,140 hectares of contiguous claims that extend over 22 kilometres, and is located approximately 25 kilometres southeast of the town of Red Lake, Ontario. The project is accessible year-round via a 15 minute drive on a paved highway which runs the length of the northern claim boundary and a network of well-maintained logging roads.

The Dixie Project hosts two principal styles of gold mineralization:

- High-grade gold in quartz veins and silica-sulphide replacement zones (Dixie Limb, Hinge and Arrow zones). Hosted by mafic volcanic rocks and localized near regional-scale D2 fold axes. These mineralization styles are also typical of the significant mined deposits of the Red Lake district.

- High-grade disseminated gold with broad moderate to lower grade envelopes (LP Fault). The LP Fault is a significant gold-hosting structure which has been seismically imaged to extend to 14 kilometres depth (Zeng and Calvert, 2006), and has been interpreted by Great Bear to have up to 18 kilometres of strike length on the Dixie property. High-grade gold mineralization is controlled by structural and geological contacts, and moderate to lower-grade disseminated gold surrounds and flanks the high-grade intervals. The dominant gold-hosting stratigraphy consists of felsic sediments and volcanic units.

About Great Bear

Great Bear Resources Ltd. is a well-financed gold exploration company managed by a team with a track record of success in mineral exploration. Great Bear is focused in the prolific Red Lake gold district in northwest Ontario, where the company controls over 300 km2 of highly prospective tenure across 4 projects: the flagship Dixie Project (100% owned), the Pakwash Property (earning a 100% interest), the Dedee Property (earning a 100% interest), the Sobel Property (earning a 100% interest), and the Red Lake North Property (earning a 100% interest), all of which are accessible year-round through existing roads.

QA/QC and Core Sampling Protocols

Drill core is logged and sampled in a secure core storage facility located in Red Lake Ontario. Core samples from the program are cut in half, using a diamond cutting saw, and are sent to Activation Laboratories in Ontario, an accredited mineral analysis laboratory, for analysis. All samples are analysed for gold using standard Fire Assay-AA techniques. Samples returning over 10.0 g/t gold are analysed utilizing standard Fire Assay-Gravimetric methods. Pulps from approximately 5% of the gold mineralized samples are submitted for check analysis to a second lab. Selected samples are also chosen for duplicate assay from the coarse reject of the original sample. Selected samples with visible gold are also analyzed with a standard 1 kg metallic screen fire assay. Certified gold reference standards, blanks and field duplicates are routinely inserted into the sample stream, as part of Great Bear’s quality control/quality assurance program (QAQC). No QAQC issues were noted with the results reported herein.

Qualified Person and NI 43-101 Disclosure

Mr. R. Bob Singh, P.Geo, VP Exploration, and Ms. Andrea Diakow P.Geo, Exploration Manager for Great Bear are the Qualified Persons as defined by National Instrument 43-101 responsible for the accuracy of technical information contained in this news release.

Results for the metallurgical test program were provided and approved by Andrew Kelly, P.Eng., of Blue Coast Research Ltd., a Qualified Person for the purpose of National Instrument 43-101.

ON BEHALF OF THE BOARD

“Chris Taylor”

Chris Taylor, President and CEO

Investor Inquiries:

Mr. Knox Henderson

Tel: 604-646-8354

Direct: 604-551-2360

Cautionary note regarding forward-looking statements

This release contains certain “forward looking statements” and certain “forward-looking information” as defined under applicable Canadian and U.S. securities laws, including forward-looking statements regarding future metallurgical test work. Forward-looking statements and information can generally be identified by the use of forward-looking terminology such as “may”, “will”, “should”, “expect”, “intend”, “estimate”, “anticipate”, “believe”, “continue”, “plans” or similar terminology. The forward-looking information contained herein is provided for the purpose of assisting readers in understanding management’s current expectations and plans relating to the future. Readers are cautioned that such information may not be appropriate for other purposes.

Forward-looking information are based on management of the parties’ reasonable assumptions, estimates, expectations, analyses and opinions, which are based on such management’s experience and perception of trends, current conditions and expected developments, and other factors that management believes are relevant and reasonable in the circumstances, but which may prove to be incorrect.

Forward-looking statements involve various risks and uncertainties and are based on certain factors and assumptions. There can be no assurance that such statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements. Important factors that could cause actual results to differ materially from the Company’s expectations, include, but are not limited to, disruptions relating to the COVID-19 pandemic and uncertainties relating to the availability and costs of financing, both of which could result in future metallurgical test work being delayed or affected.

Great Bear undertakes no obligation to update forward-looking information except as required by applicable law. Such forward-looking information represents management's best judgment based on information currently available. No forward-looking statement can be guaranteed and actual future results may vary materially. Accordingly, readers are advised not to place undue reliance on forward-looking statements or information.