Fireweed Zinc Announces Successful Ore Sorting Results for Boundary Zone Mineralization

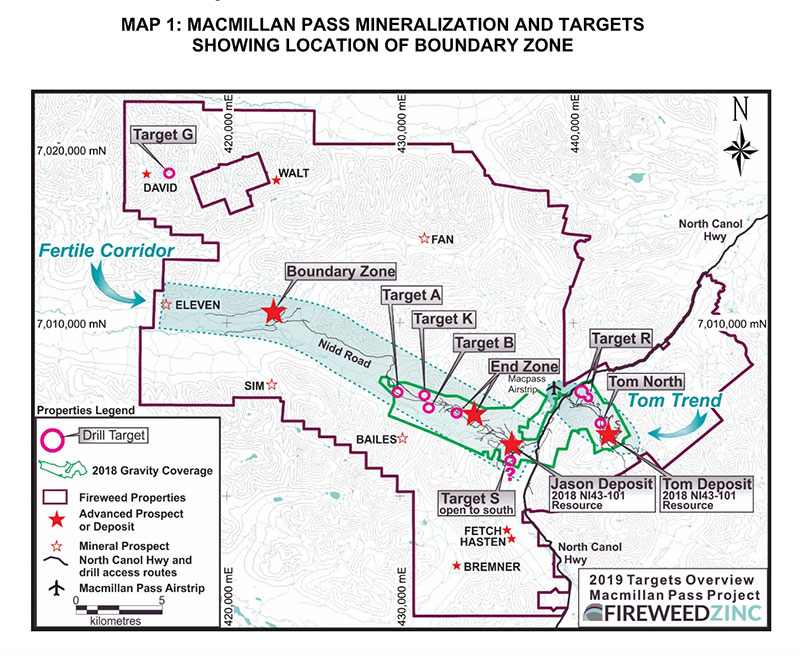

Vancouver, British Columbia: FIREWEED ZINC LTD. (“Fireweed” or the “Company”) (TSXV: FWZ) is pleased to announce positive results from an initial preconcentration test using state-of-the-art X-ray Fluorescence (“XRF”) ore sorting technology on samples from the Boundary Zone at the Macmillan Pass Zinc Project, Yukon, Canada. Boundary Zone is a discrete bulk-tonnage, advanced exploration target located 15 kilometres northwest of the Jason zinc-lead-silver deposit.

The principal results of the XRF test are summarized below:

- Potential to upgrade the feed grade from 2.5% Zn to 5% Zn

- Rejection rate expected between 70-50%, with zinc recoveries ranging from 80% to 85%

- Mass pull* ranged from 30% to 50%. In other words, rejection fraction ranged from 70% to 50%.

- In practical terms, these results show potential to upgrade feed material from the test feed grade of 2.5% Zn to approximately 5% Zn with recovery of 80-85% of the zinc at low cost

- The analysis in this study is based on the assumption that 25% of the feed had fines (-12mm) which cannot be processed in the ore sorter. The fines will bypass the sorter and combine with the ore sorter product. The final grade of 5% Zn achieved is after combining the ore sorter product with the fines which are assumed to have a grade of 2.5% Zn

*Mass pull is a measure of the weight percentage of material mass recovered from the XRF sorting test into a preconcentrate stream that would feed a downstream processing plant. The smaller the number, the lower the throughput tonnes required in the downstream processing plant, lowering costs and tailings production. In other words, the smaller the mass pull number the more low-grade and waste material is rejected from the sample.

CEO Statement

Brandon Macdonald, CEO, stated “These are excellent ore sorting results that have the potential to significantly impact the overall economics of the Macmillan Pass project. These results suggest that we may be able to reject 50% to 70% of low-grade and waste rock at low cost near a potential open pit operation at Boundary with less than 15% loss of zinc mineralization before material is transported to a central processing plant at Tom. We have now begun the next step and moved the drill to Boundary to both confirm and step out from historic holes, as well as obtain a two tonne sample to confirm that these ore sorting results may be obtained on a larger scale and to provide additional material for metallurgical testing. If the larger test is successful, we can then incorporate the benefits of an XRF ore sorting system at Boundary into a revised PEA economic study along with upgraded information from recent drilling at Tom, Jason and End Zones.

Pre-Concentration Test Work Details

The ore sorting test work was carried out by Sacré-Davey Engineering, a highly respected Canadian engineering consultancy with a specialization in ore sorting. These test results are based on bench-scale test work conducted at the University of British Columbia on 436 rock samples representing the range of variability in the lithologies and grade distribution at Boundary Zone. These preliminary tests indicate that it may be possible to significantly pre-concentrate the low-grade material and reduce the processing costs at Boundary Zone with an XRF sorting system. X-Ray Transmission (XRT), electromagnetic (EM) and dense media separation (DMS) sorting tests were also carried out but results were not as promising as XRF.

Readers are cautioned that the sorting results reported in this news release were preliminary tests and that additional successful test work on larger sample sizes will be required before such information may be used in any economic study. Furthermore, no metallurgical work has yet been performed on samples from Boundary Zone and it is uncertain how the geology there, which is different from the Tom and Jason deposits, would influence metal recovery and concentrate grade, and therefore metal payability. Further ore sorting and metallurgical test work is planned.

About XRF Ore Sorting

XRF sorting is a state-of-the-art technology that is currently used at over 50 operations across the world including Hecla’s San Sebastian Mine in Mexico and AngloAmerican’s Mogalakwena mine in South Africa1. Typically, it utilizes an XRF sensor to distinguish and measure surface metal abundances on rock pieces moving on an enclosed conveyor belt unit. The XRF readings for each individual rock are then analysed by high speed discriminating software to distinguish and flag rocks with metal values above and below a set threshold. At the end of the conveyor belt, focussed high pressure air jets or mechanical levers then separate the designated higher grade rock pieces for processing and reject low-grade and waste pieces. The amenability to ore sorting depends on the material characteristics of a deposit. The Boundary Zone samples responded positively to XRF testing because zinc values on the surfaces of individual rock pieces correlate closely with the overall zinc assays of those rocks.

Boundary Zone Background

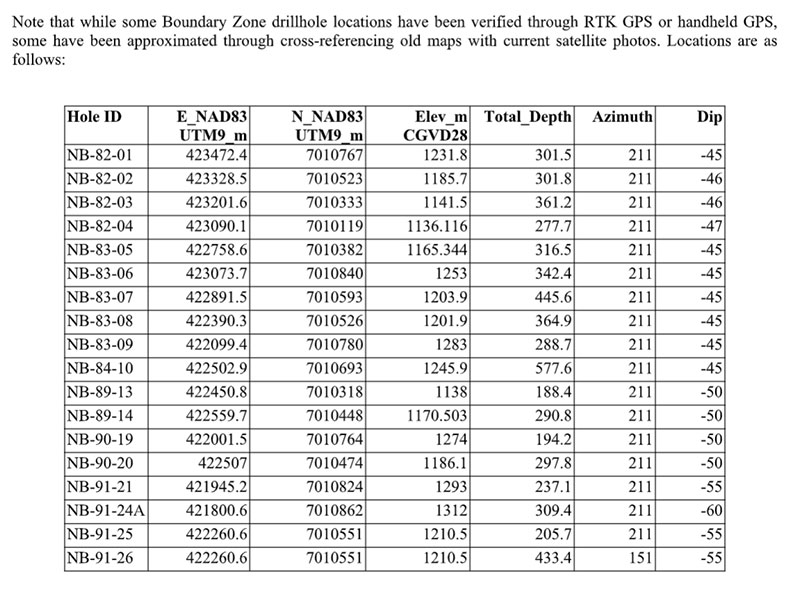

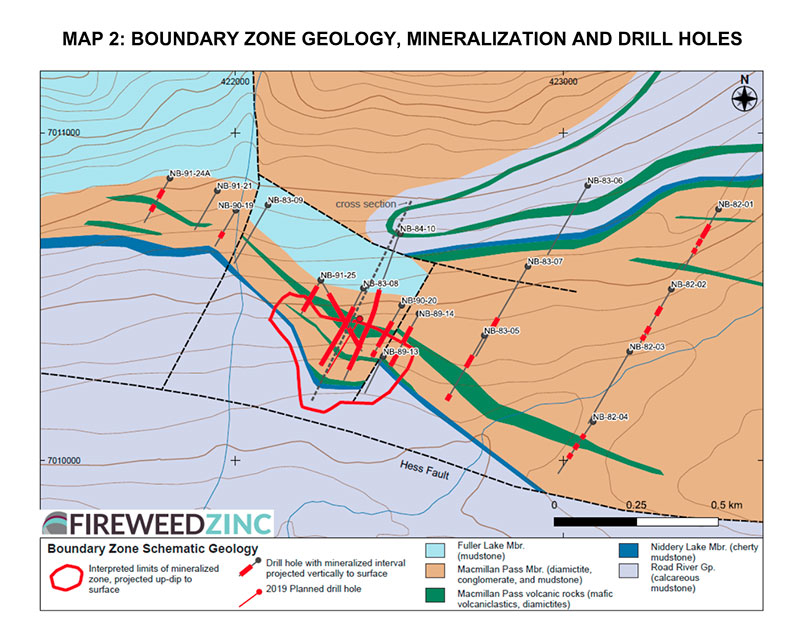

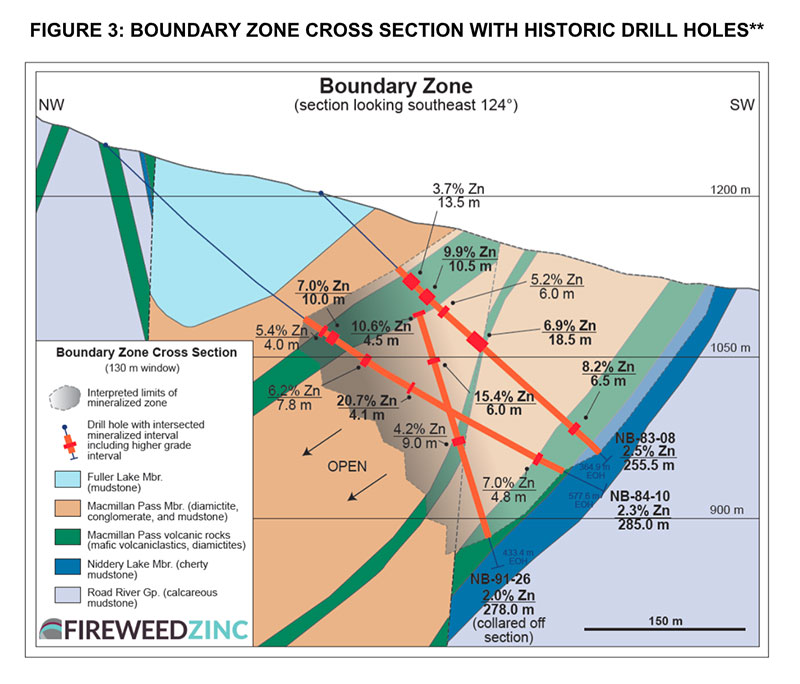

Boundary Zone is a bulk-tonnage zinc exploration target that occurs at surface in an area potentially suitable for open-pit mining. Known mineralization is spread over an area almost two kilometres long and 200 to 800 metres wide. Boundary Zone has been tested with 24 historic core holes totaling over 7,250 metres of drilling. Mineralization drilled in a central area is 350 metres long and has a true thickness of up to 240 metres with historic drilling grades averaging 2-2.5% Zn that includes intervals of higher grade (see Figure 3 & Table 1). The zone has only been tested to a depth of 200 metres down dip and remains open to depth and along trend for further exploration. The Boundary mineralization consists of sphalerite-siderite-pyrite and minor galena in veins, stockworks, interstitial disseminations, and as replacement of matrix and clasts within coarse clastic rocks. The Boundary Zone is located in a distinct sub-basin of Earn Group rocks, adjacent to a major synsedimentary structure and contains large volumes of boulder diamictites and strongly siderite-altered mafic volcaniclastic rocks, indicating that the basin underwent rapid tectonic extension—a similar setting to the Tom and Jason areas. The presence of a major synsedimentary fault system, a distinct sub?basin, volcanic rocks, abundant zinc mineralization, and strong alteration indicate the area is host to a robust zinc mineralizing system which has been under-explored to date.

This news release contains historic drill results that were copied from public reports written by major companies Teck Resources Ltd and Cominco Ltd. Fireweed believes these data to be reliable but no qualified person has carried out sufficient verification work. Fireweed considers these historical data to be relevant in guiding planning of work programs and evaluating the potential of the Boundary Zone and is including these data in this news release for information purposes only.

NI43-101 Qualified Persons Statement

Technical information in this news release regarding XRF has been reviewed and approved by Preetham Nayak, P.Eng, of Sacré-Davey Engineering, an independent consultant to Fireweed Zinc and a ‘Qualified Person’ as defined under Canadian National Instrument 43?101. Other technical information in this news release (not related to XRF work) has been reviewed and approved by Gilles Dessureau, P.Geo, Vice President, Exploration and a ‘Qualified Person’ as defined under Canadian National Instrument 43?101.

Amendment to MAC Claims Option Agreement

The Company has signed an amendment to the option agreement on the MAC claims at Macmillan Pass. The amendment reduces the cash payment and issues shares for the balance of the option payment due July 24, 2019. The option payment is changed from $95,000 to $50,000 plus 95,000 shares. In all other respects, the option agreement remains unchanged. This amendment is subject to TSX Venture Exchange approval.

About Fireweed Zinc Ltd. (TSXV: FWZ): Fireweed Zinc is a public mineral exploration company focused on zinc and managed by a veteran team of mining industry professionals. The Company is advancing its district-scale 544 km2 Macmillan Pass Project in Yukon, Canada, which is host to the 100% owned Tom and Jason zinc-lead-silver deposits with current Mineral Resources and a PEA economic study (see Fireweed news releases dated January 10, 2018, and May 23, 2018, respectively, and reports filed on www.sedar.com for details) as well as the Boundary Zone and End Zone which have significant zinc-lead-silver mineralization drilled but not yet classified as mineral resources. The project also includes option agreements on large blocks of adjacent claims (MAC, MC, MP, Jerry, BR and NS) which cover exploration targets in the district where previous and recent work identified zinc, lead and silver prospects, and geophysical and geochemical anomalies in prospective host geology.

Additional information about Fireweed Zinc and its Macmillan Pass Zinc Project can be found on the Company’s website at www.FireweedZinc.com and at www.sedar.com.

ON BEHALF OF FIREWEED ZINC LTD.

“Brandon Macdonald”

CEO & Director

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This news release may contain “forward-looking” statements and information relating to the Company and the Macmillan Pass Project that are based on the beliefs of Company management, as well as assumptions made by and information currently available to Company management. Such statements reflect the current risks, uncertainties and assumptions related to certain factors including but not limited to, without limitations, exploration and development risks, expenditure and financing requirements, general economic conditions, changes in financial markets, the ability to properly and efficiently staff the Company’s operations, the sufficiency of working capital and funding for continued operations, title matters, First Nations relations, operating hazards, political and economic factors, competitive factors, metal prices, relationships with vendors and strategic partners, governmental regulations and oversight, permitting, seasonality and weather, technological change, industry practices, and one-time events. Additional risks are set out in the Company’s prospectus dated May 9, 2017, and filed under the Company’s profile on SEDAR at www.sedar.com. Should any one or more risks or uncertainties materialize or change, or should any underlying assumptions prove incorrect, actual results and forward-looking statements may vary materially from those described herein. The Company does not undertake to update forward?looking statements or forward?looking information, except as required by law.

Footnotes:

- References for commercial XRF ore sorting operations: http://radosxrf.com

https://www.hecla-mining.com/wp-content/uploads/2019/03/HMC-Tech-News_02-28-19.pdf?v=022110

http://www.radosxrf.com/wp-content/uploads/2015/12/Run-of-Mine-Ore-Sorting-Proof-of-Concept-Plant-videos-Removed-1-3.pdf?v=022110

Table 1: Boundary Zone Historic Drill Intersection Highlights

| Hole ID (dip, azimuth) | From (m) | To (m) | Interval (m) | % Zn | % Pb | |

|---|---|---|---|---|---|---|

| NB-82-01 (-45, 210) |

88.9 | 97.0 | 8.1 | 3.7 | ||

| 107.9 | 118.4 | 10.5 | 3.4 | |||

| 121.5 | 133 | 11.5 | 5.1 | |||

| including | 129.2 | 130.7 | 1.5 | 13.9 | ||

| 161.4 | 170.2 | 8.8 | 6.0 | |||

| 206.4 | 209.1 | 2.7 | 8.0 | |||

| NB-82-02 (-46, 210) |

100.4 | 106.2 | 5.8 | 3.0 | ||

| 119.7 | 122.2 | 2.5 | 3.2 | |||

| 201.2 | 212.8 | 11.6 | 4.4 | |||

| 244.9 | 247.9 | 3.0 | 4.7 | |||

| NB-82-04 (-47, 214) |

79.8 | 80.3 | 4.5 | 3.2 | ||

| 131.8 | 137.8 | 6.0 | 4.4 | |||

| 183.1 | 186.8 | 3.7 | 3.8 | |||

| NB-83-05 (-45, 210) |

110.0 | 122.0 | 12.0 | 3.3 | ||

| 143.0 | 147.5 | 4.5 | 5.8 | |||

| 304.0 | 312.8 | 8.8 | 3.6 | 0.2 | ||

| NB-83-07 (-45, 210) |

268.0 | 279.4 | 11.5 | 3.5 | ||

| 290.0 | 301.0 | 11.0 | 4.1 | |||

| including | 294.5 | 301.0 | 6.5 | 5.9 | ||

| NB-83-08 (-45, 210) |

99.5 | 355.0 | 255.5 | 2.5 | 0.3 | |

| including | 110.0 | 234.5 | 124.5 | 3.4 | 0.2 | |

| including | 132.5 | 143.0 | 10.5 | 9.9 | ||

| including | 191.5 | 210.0 | 18.5 | 6.9 | ||

| including | 197.0 | 201.5 | 4.5 | 16.4 | ||

| including | 222.0 | 234.5 | 12.5 | 2.8 | 1.8 | |

| including | 294.0 | 323.5 | 29.5 | 3.5 | 0.5 | |

| including | 317.0 | 323.5 | 6.5 | 8.2 | 0.7 | |

| NB-84-10 (-45, 210) |

248.0 | 533.8 | 285.0 | 2.3 | 0.2 | |

| including | 248.0 | 251.7 | 3.7 | 4.2 | ||

| including | 264.0 | 268.0 | 4.0 | 5.4 | ||

| including | 272.5 | 283.0 | 10.5 | 7.0 | ||

| including | 275.5 | 280.0 | 4.5 | 11.1 | ||

| including | 313.5 | 321.3 | 7.8 | 6.2 | ||

| including | 316.8 | 320.3 | 3.5 | 10.2 | ||

| including | 366.5 | 370.6 | 4.1 | 20.7 | 0.4 | |

| including | 440.0 | 444.5 | 4.5 | 3.3 | 0.4 | |

| including | 505.9 | 533.8 | 27.9 | 3.7 | 0.9 | |

| including | 505.9 | 510.7 | 4.8 | 7.0 | 1.2 | |

| including | 526.8 | 533.8 | 7.0 | 3.8 | 1.8 | |

| NB-89-14 (-50, 210) |

84.5 | 148.2 | 63.7 | 2.0 | ||

| including | 95.0 | 108.0 | 13 | 3.8 | ||

| including | 137.7 | 140.7 | 3.0 | 5.7 | ||

| including | 147.8 | 148.2 | 0.4 | 19.6 | ||

| 221.0 | 222.8 | 1.8 | 28.3 | |||

| 227.8 | 229.6 | 0.8 | 12.3 | |||

| 252.3 | 254.8 | 2.5 | 28.3 | 0.4 | ||

| 267.8 | 268.3 | 0.5 | 6.7 | 2.9 | ||

| NB-90-19 (-50, 210) |

130.6 | 139.9 | 9.3 | 10.7 | 0.9 | |

| including | 131.7 | 138.4 | 5.9 | 15.3 | 1.2 | |

| NB-90-20 (-50, 210) |

101.0 | 185.5 | 84.5 | 2.8 | 0.2 | |

| including | 141.5 | 165.0 | 23.5 | 3.3 | ||

| including | 175.5 | 185.5 | 10.0 | 5.4 | 1.5 | |

| 199.0 | 215.0 | 16.0 | 1.5 | 0.5 | ||

| including | 207.5 | 215.0 | 7.0 | 4.0 | 3.1 | |

| 261.0 | 268.5 | 7.5 | 4.7 | 0.3 | ||

| NB-91-24A (-60, 210) |

96.0 | 125.5 | 29.5 | 3.2 | ||

| including | 113.5 | 121.0 | 7.5 | 7.1 | ||

| 202.5 | 218.5 | 16.0 | 3.8 | |||

| including | 209.5 | 217.0 | 7.5 | 7.0 | ||

| NB-91-25 (-55, 210) |

50.5 | 178.0 | 127.5 | 1.8 | 0.1 | |

| including | 134.0 | 178.0 | 44.0 | 2.3 | 0.1 | |

| NB-91-26 (-55, 150) |

96.0 | 100.5 | 4.5 | 1.9 | ||

| 117.0 | 395.0 | 278.0 | 2.0 | |||

| including | 117.0 | 124.5 | 7.5 | 9.2 | ||

| including | 147.5 | 152.0 | 4.5 | 10.6 | ||

| including | 189.5 | 195.5 | 6.0 | 15.4 | ||

| including | 279.0 | |||||